Sandy Aehle

Sandy earned her Master of Science in biological science from the University of Missouri and has over 35 years of experience in foodborne pathogen research and mitigation strategies.

Dr. Elizabeth Krushinskie

Dr. Krushinskie earned her DVM degree from Colorado State University, a PhD in Veterinary Microbiology from the University of Minnesota, and was board certified by the American College of Poultry Veterinarians.

Strategies for Salmonella Control in Turkey Production

When looking at strategies to manage and mitigate Salmonella, taking a holistic approach will help build a foundation that allows producers to reduce Salmonella contamination at the farm level. Having good biosecurity practices in place can prevent the introduction and spread of infectious diseases, including Salmonella. Effective biosecurity requires compliance, and it is the responsibility of everyone involved in raising turkey flocks to implement biosecurity practices they can control on their premises.

Managing Salmonella in Turkey Production

Poultry can be latent carriers, shedding and spreading Salmonella, especially when stressed. Preventing exposure and colonization as early as possible reduces shedding and the subsequent spread of Salmonella.

Biosecurity procedures outlined in a Salmonella prevention program minimize the chances for Salmonella and other disease agents to enter a production site. Ideally, every producer should have a site-specific plan that includes criteria for implementing effective biosecurity practices, as well as a regular monitoring and testing scheme designed to identify sources of potential Salmonella contamination.

Routine monitoring of samples from hatch trays or poult boxes provides an opportunity to identify Salmonella serotypes that have been transferred from the hens to the poults. This can provide useful information to compare Salmonella field serotypes identified from commercial birds to serotypes in the breeders and make changes to the vaccination program as warranted. Identifying serotypes that challenge breeder flocks can help with managing a breeder vaccination program that includes both live vaccines and custom-blend autogenous vaccines.

In addition, anything with legs can carry Salmonella into a barn: humans, beetles, flies, rodents. An effective rodent and pest control program is especially critical to the successful control of Salmonella contamination in poultry.

Poultry barns should have anterooms where producers, service techs and visitors can put on dedicated coveralls and over-boots as they enter the barn and remove and dispose of them appropriately prior to leaving the barn. Foot baths and hand sanitizer should be used when entering and exiting the barn. These and other on-farm biosecurity practices have been shown to effectively reduce the risk of carrying Salmonella from one barn to another.

How Vaccines Help Control Salmonella

In addition to implementing biosecurity measures, turkey producers can also manage Salmonella with vaccination programs in turkey breeders and in commercial flocks.

Salmonella vaccines have been shown to significantly reduce Salmonella infections in poultry. When used together in a breeder vaccination program, live and inactivated Salmonella vaccines stimulate the development of long-term immunity, reduce shedding of wild types, and provide protective maternal antibodies to offspring.

In addition to the early protection provided by maternal antibodies, a coarse spray application of a live vaccine, like AviPro® Megan® Egg, to day-old commercial poults also provides an additional layer of protection by providing a competitive exclusion effect and stimulating the immune system to reduce infections by wild types within hours of hatch.

This dual mode of action provided by live and inactivated Salmonella vaccines has a significant impact on reducing vertical transmission of Salmonella from hen to poult, which in turn reduces contamination in turkeys entering the processing plant.

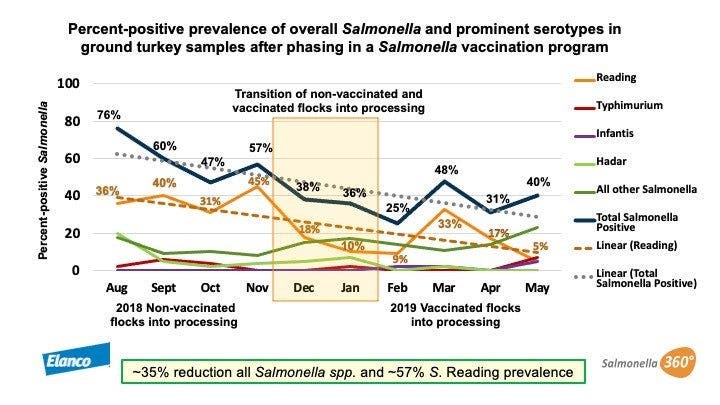

Elanco partnered with a turkey producer to examine the effectiveness of a live vaccine in turkeys to reduce Salmonella contamination in ground samples. The study involved determining the baseline level of Salmonella contamination in the operation over a four-month period prior to implementing vaccination. Following the baseline period, the turkey producer began vaccinating commercial poults with AviPro Megan Egg at placement and again at around three weeks of age. Organic and antibiotic-free vaccinated toms entered the processing plant in mid-November 2018, and vaccinated conventional toms entered the plant in late January 2019.

A total of 557 ground turkey samples were collected between August 8, 2018, and May 31, 2019, to determine the prevalence and serotypes of Salmonella present during the pre-vaccination period, in the vaccination transition period when mixed populations of non-vaccinated and vaccinated flocks entered processing, and after January 21, 2019 when 100% of the flocks that entered processing were fully vaccinated.

Results

The graph below shows that Salmonella prevalence overall was reduced by approximately 35% in ground turkey samples tested during the period when 100% of fully vaccinated flocks entered processing.1 In addition, there was a 57% reduction in S. Reading prevalence, a serotype of significant concern to the turkey industry and to public health.

Managing a Salmonella Vaccination Program

There are many factors to take into consideration when implementing a Salmonella vaccination program. Having a Salmonella prevention program in place that includes staff training ensures on-farm biosecurity practices and vaccination protocols are being followed.

After hatch a turkey poult’s intestinal tract is relatively sterile and has not had significant exposure to Salmonella. Introducing a Salmonella vaccine shortly after hatch or upon placement in the barn prepares poults with the dual action of inhibition of colonization by wild types in the environment and stimulation of innate immunity. A second dose applied at three weeks of age provides a boost to enhance long-lasting protective immunity.

The recommended application method is to apply a coarse spray to poults at the hatchery or at placement in the brood barn. Poult boxes can be placed in lines of 10 on the floor of the house and a coarse spray of vaccine solution applied to each box. Poults should remain in the box five to ten minutes after vaccination to allow adequate preening before they are released onto the litter. Once poults are three weeks of age, a vaccine booster application can be administered through the drinking water or by coarse spray.

While it’s important for companies to implement a Salmonella control program based on a SWOT analyses of strengths, weaknesses, opportunities and threats, Salmonella vaccines are a valuable and effective tool available to the producer that can be used to aid in the reduction of systemic and environmental Salmonella in live turkey production. Your plan should cover farm management, employee training, biosecurity, monitoring, surveillance and a regular review of the results so corrective actions can be taken.

A written plan helps connect the dots from the boots on the ground up to management. It also helps put checks and balances in place that allow companies to ensure they are taking essential steps to deliver the safest product possible.

To learn more about AviPro Megan Egg and how it can help control Salmonella in your turkey operation, please contact your Elanco sales team member.

Tags

Salmonella

Salmonella Control

Salmonella transmission

Salmonella vaccine for poultry

Turkey

Biosecurity in poultry

¹ Elanco Animal Health. Data on file.